Marginpar has specialised in creating the most extraordinary cut flowers for over 30 years, establishing itself as a prominent flower producer. They grow a diverse range of over 100 beautiful flowers on their farms in Kenya, Ethiopia, Tanzania and Zimbabwe.

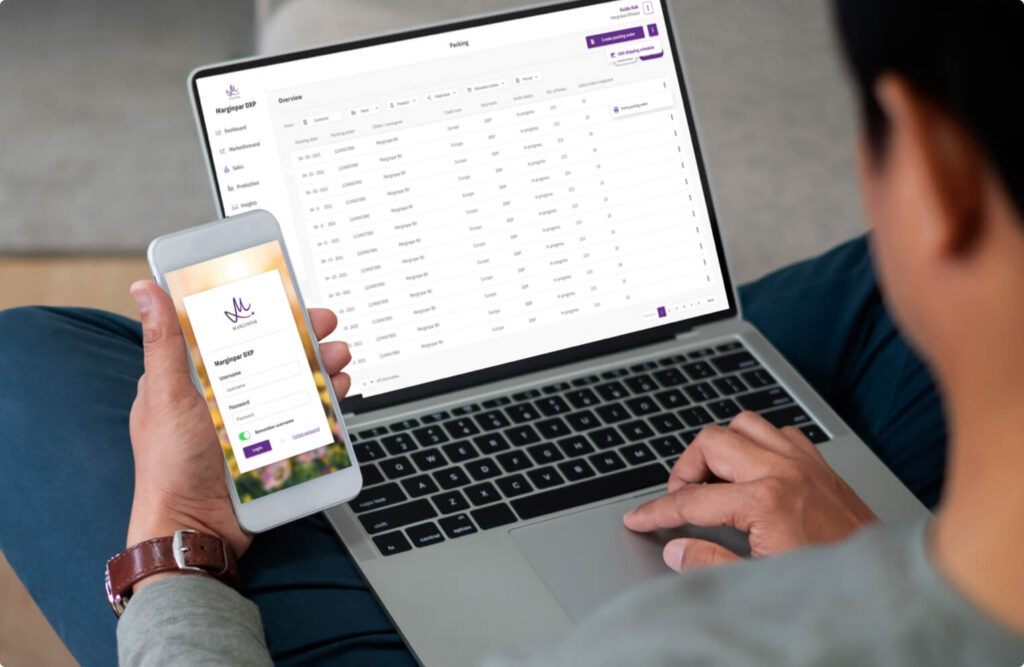

Customised ERP

A customised ERP built for end-to-end supply chain management.

Invoice processing

Automated invoicing tools implemented to minimise errors and speed up financial processes.

Integrated sites

Developed a unified system to connect African farms to the head office in Aalsmeer.

Market demand optimisation

Prediction models designed to improve inventory management and resource utilisation.

No uniform system around the supply chain.

Manual processes caused inefficiencies and errors.

The varying needs of farms and head offices were difficult to meet.

Difficulty effectively matching supply and demand.

Problem statement

In a fast-growing market, it is important that Marginpar continues to differentiate itself from the intense competition. To stay ahead of the competition, they want an application in which everything in the process, from start to finish, can be easily managed. This application must not only be efficient, but also flexible enough to meet the various needs of the different links in the chain.

Desired Solution

Marginpar wishes to develop an ERP system that can manage all aspects of its supply chain. By investing in this system, the company can streamline operational processes, reduce costs and improve customer service. This ERP solution will need to consist of several phases, such as procurement, inventory management, production planning, distribution, sales and finance.

Built the DXP ERP system to manage the entire supply chain.

Seamless matching of supply and demand with DXP.

Automated invoice processing to reduce errors and save time.

Centralised operations for farms and head office on one platform.

Solution

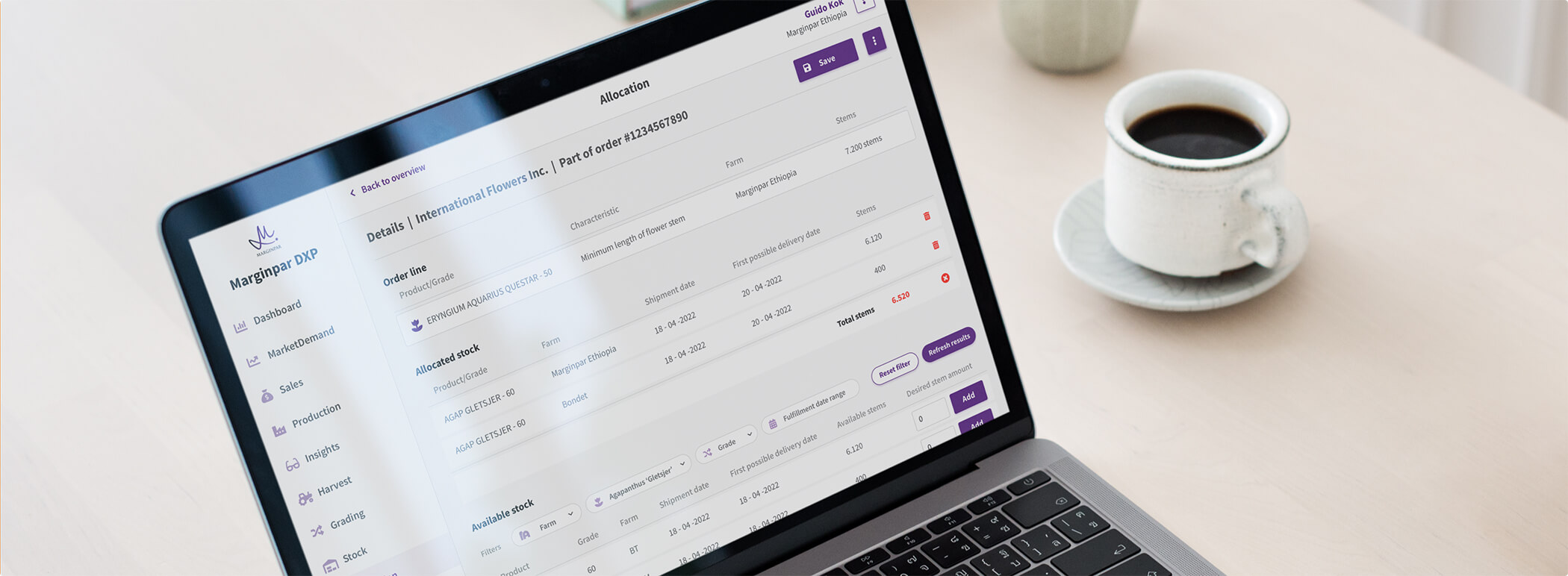

To realise this desired solution, Emendis was called in. We built an ERP system, called DXP, which both the farms in Africa, and the head office in Aalsmeer work with. Using Digital Experience Platform (DXP), companies can transform traditional sales strategies into seamless sales experiences. This enables staff to easily combine supply and demand with optimal capacity utilisation, while meeting specific requirements from Aalsmeer regarding delivery to direct customers or auctions.

Need a similar solution?

Let’s talk!

Methodology

All invoices received by the PP group are automatically read into the P2P system. Only the necessary information is captured, such as the invoice number, company name, IBAN and the amount to be paid. This automation speeds up the invoice processing process and minimises manual input errors.

Proud partners of Emendis:

Emendis works for, among others